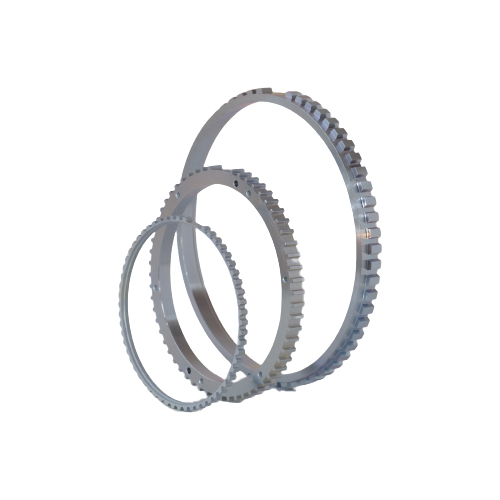

Ring Gear

Ring gears are used for starting any internal combustion engine. The drive from the starter motor gets transferred to the engine through a ring gear, which is mounted on a flywheel or a flex plate. In order to make the starting noise free, ring gear class requirements have changed to Class 10. Due to wide use of start stop engines, number of starts has increased manyfold necessitating the use of finer class of gear and higher hardness within narrow tolerance bands.

Manufacturing range :

Timing Rings

Timing rings are used for detecting the position of piston in the engine and ensure firing of the engine at a particular point. The position is detected by missing teeth on the part. Timing rings are mounted on the flywheel or drive plate assembly.

Manufacturing range :

Inertia Rings

Inertia rings are mounted on the drive plates to maintain moment of inertia.

Manufacturing range :

Flex Plate Assemblies

Flex plate assemblies are used in vehicles with automatic transmission. It is an assembly of a sheet metal plate on the outer diameter of which, a ring gear is mounted. The assembly is a connection between the engine and the torque converter.

Manufacturing range :